chintu.gurbani@gmail.com - GST NO. : 09AAFCI7462N1ZW

- Send Email

2.21 Lac / Piece

| Business Type | Manufacturer, Supplier |

| Warranty | 1 Year |

| Material | Aluminium 6061 |

| Country of Origin | India |

| Click to view more | |

Product Details

Driven Type

Electric

Usage

Industrial

Output Capacity

2000

Power Consumption

220

Brand Name

Invariance Automation

Product Code

INVSMT-2E

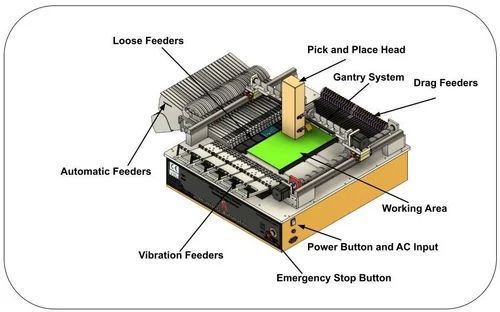

Meet the INVSMT-2E from Invariance Automation; a powerful desktop solution for high-mix SMT assembly. Engineered for precision and efficiency, it brings your electronic designs to life with professional speed and reliability.

This machine is ideal for prototyping, R&D, and medium-volume production, offering a perfect balance of advanced features. Crucial Specs at a Glance :

- Speed: 2500 CPH (with vision) from its dual placement heads.

- Precision: Unwavering ±0.025mm accuracy, thanks to its top & bottom HD vision alignment system. Component Range: Handles everything from tiny 0402 parts to larger LEDs, SOPs, and QFNs. Feeder System: Highly versatile, supporting up to 24 Yamaha CL Auto feeders, IC Trays, auto-drag, and vibration feeders.

- Max PCB Size: Generous 320mm×320mm work area.

- Motion Control: Reliable closed-loop step-servo motors with encoders for guaranteed placement accuracy. Powered by a robust industrial 32-bit motherboard with both Windows and Linux support.

- Dual Placement Heads for Enhanced Throughput: At the heart of the machine are two high-precision placement heads. This dual-head design works in tandem to significantly reduce assembly time and maximize your output. The system is capable of achieving impressive mounting speeds of up to 3000 CPH (Components Per Hour) without vision and 2500 CPH with its advanced vision alignment system engaged.

- High-Precision Vision Alignment System: Quality and accuracy are paramount. The INVSMT-2E is equipped with a sophisticated vision detection system, featuring both top and bottom HD cameras. This up-and-down camera configuration ensures that every component, from the smallest chip to the most complex integrated circuit, is accurately identified, oriented, and placed. This system is crucial for working with fine-pitch components and BGAs, delivering an exceptional placement precision of ±0.025mm.

- Versatile Component and Feeder Support: The INVSMT-2E offers unparalleled flexibility. It is capable of handling a vast range of SMD components, from minute 0402 packages up to large 5050 components, LEDs, SOPs, QFNs, and more. Support for up to 24 Yamaha CL Auto feeders (both Pneumatic and Electric). An IC Tray Feeder for larger, sensitive components. 20 Auto-drag Feeders and 2 Vibration Feeders (Support upto 5 vibration feeder) for tube or loose components. This extensive support ensures you can handle virtually any component mix your designs require.

- Advanced Closed-Loop Motion Control: Experience superior reliability and repeatability thanks to the machine's Step-Servo motor system. Unlike open-loop stepper motors, this system features encoder-based closed-loop control. The encoder provides constant positional feedback to the controller, instantly correcting for any potential deviations and eliminating the risk of lost steps. This results in smoother, quieter, and more accurate gantry movement.

- Robust and Flexible Operating Platform: Built on a solid foundation, the INVSMT-2E is powered by an industrial-grade HAL 32-bit motherboard, ensuring stable and reliable operation even during long production runs. To integrate seamlessly into your existing workflow, the machine offers the flexibility of running on either a Windows or Linux operating system, controlled via an external monitor with standard VGA/HDMI connectivity.

- Compatible with Openpnp Software: Completely free software for controlling SMT pick and place machines, with no licensing fees. Backed by a strong global community of developers and users who provide support, and continuously improve the software.

- CUSTOM SOFTWARE INVSMT-PNP: A specialized software solution that programs and controls pick and place machines to perform precise, automated pick and place tasks tailored to unique components and workflows.

Looking for "Desktop Smt Pick & Place Machine" ?

Piece